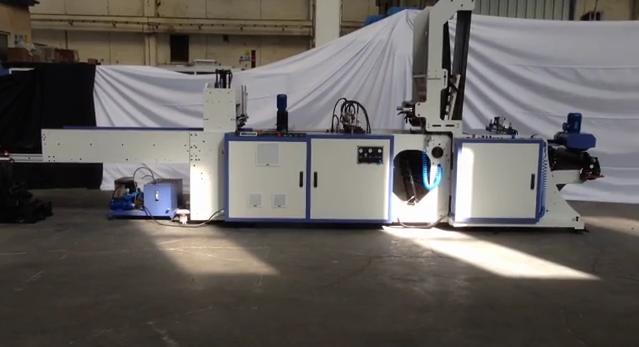

MS-425 GP, MS-500 GP, MS-600 GP

Single Line, T-Shirt Bag Making Machine with Fully Automatic Press and Post Gusseting Unit

| MS-425 GP | MS-500 GP | MS-600 GP | |

|---|---|---|---|

| Poşet Genişliği(mm) | 450 | 450 | 550 |

| Poşet Boyu(mm) | 280-700 | 280-700 | 350-1000 |

| Film Kalınlığı(mm) | 0,007-0,030 | 0,007-0,030 | 0,012-0,070 |

| Üretim Hızı(adet/dk) | 350 | 300 | 250 |

| Toplam Hava Tüketimi(litre/dk) | 300 | 250 | 300 |

| Toplam Güç(kw) | 15 | 15 | 15 |

Unwinding and Post Gussetting Unit:

» Hydraulic Roll Lifting ,Edge Guiding and Unwinding Unit

» Post Gusseting System. Easy adjustment mechanism.

Cutting and Sealing(welding) Unit

» Servo Motor and Invertor Control System

» Bag lenght, set number can be changed via screen.Bag counting, machine speed can be seen on the screen.

» There is one photocell. Ability to produce printed bags and none-printed bags.

» Ability to work with High Density Poly Ethilene(HDPE) , Low Density Poly Ethilene(LDPE) and Recycled Polyethilene materials.

» The machine would stop and give information on the screen when `Roll is empty`, `The print mark is not in right position`, `The bags are jammed on the welding area`.

» Thanks to zigzag unit, the welding lines are not superimposed on the other bag`s welding line.

SingleLine Full Automatic Bag Punching Section

» Full automatic working with Siemens Plc and Operator Panel.

» The Bag Length is entered on Operator Panel.Then Machine works completely automatic. You don’t need to adjust sensor places when you have changed the lenght

» Hydraulic cylinder ,valve , motor and pressure adjustment switch system for perfect cutting quality.

» Extractors Pneumatic Valve and Piston for punching waste for each line.

» Lower Disc is rotated by AC motor in order to change the cutting point of the Punching Knife.

» The bag packages are arranged in a row on the conveyor.The conveyor is included to machine as standard. Extendend conveyor belt saves your time to pact.

» Hydraulic Roll Lifting ,Edge Guiding and Unwinding Unit

» Post Gusseting System. Easy adjustment mechanism.

Cutting and Sealing(welding) Unit

» Servo Motor and Invertor Control System

» Bag lenght, set number can be changed via screen.Bag counting, machine speed can be seen on the screen.

» There is one photocell. Ability to produce printed bags and none-printed bags.

» Ability to work with High Density Poly Ethilene(HDPE) , Low Density Poly Ethilene(LDPE) and Recycled Polyethilene materials.

» The machine would stop and give information on the screen when `Roll is empty`, `The print mark is not in right position`, `The bags are jammed on the welding area`.

» Thanks to zigzag unit, the welding lines are not superimposed on the other bag`s welding line.

SingleLine Full Automatic Bag Punching Section

» Full automatic working with Siemens Plc and Operator Panel.

» The Bag Length is entered on Operator Panel.Then Machine works completely automatic. You don’t need to adjust sensor places when you have changed the lenght

» Hydraulic cylinder ,valve , motor and pressure adjustment switch system for perfect cutting quality.

» Extractors Pneumatic Valve and Piston for punching waste for each line.

» Lower Disc is rotated by AC motor in order to change the cutting point of the Punching Knife.

» The bag packages are arranged in a row on the conveyor.The conveyor is included to machine as standard. Extendend conveyor belt saves your time to pact.