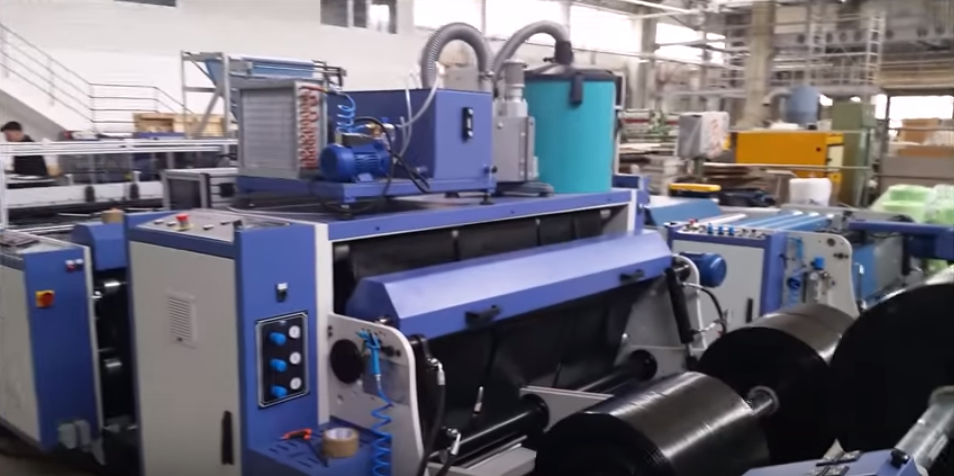

BS-1100 M, BS-1300 M, BS-1600 M

Cold Cutting(Serrated) System, Bottom Seal Bag Making Machine with Automatic Double Folding System

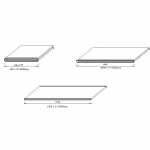

| BS-1100 M | BS-1300 M | BS-1600 M | |

|---|---|---|---|

| Bag Width(mm) | 1100 | 1300 | 1600 |

| Bag Lenght(mm) | 300-3000 | 300-3000 | 300-3000 |

| Thickness of Film(mm) | 0,010-0,150 | 0,010-0,150 | 0,010-0,300 |

| Total Thickness of Film(mm) | 0,300 | 0,300 | 0,600 |

| Production Speed (pieces/min) | 150 | 125 | 100 |

| Total Air Consumption(liter) | 400 | 400 | 500 |

| Total Installed Power(Kw) | 16 | 16 | 16 |

» Double Folding system automatic robot unit.

» Bottom Sealing Sack and Heavy Duty Sack production

» Cold cutting System.

» All Sacks are stacked on cold pins those are located 1 cm inside from the open side of the sack

» Sack packs -those are folded One time or Double time – are arranged in a row on conveyor.

» Servo Motor and Invertor Control System.

» Bag lenght, set number can be changed via screen. Bag counting, machine speed can be seen on the screen

» There is one photocell. Ability to produce printed bags and none-printed bags

» Ability to work with High Density Poly Ethilene(HDPE) , Low Density Poly Ethilene(LDPE) and Recycled Polyethilene materials.

» The machine would stop and give information on the screen when `Roll is empty`, `The print mark is not in right position`, `The bags are jammed on the welding area`.

» Bottom Sealing Sack and Heavy Duty Sack production

» Cold cutting System.

» All Sacks are stacked on cold pins those are located 1 cm inside from the open side of the sack

» Sack packs -those are folded One time or Double time – are arranged in a row on conveyor.

» Servo Motor and Invertor Control System.

» Bag lenght, set number can be changed via screen. Bag counting, machine speed can be seen on the screen

» There is one photocell. Ability to produce printed bags and none-printed bags

» Ability to work with High Density Poly Ethilene(HDPE) , Low Density Poly Ethilene(LDPE) and Recycled Polyethilene materials.

» The machine would stop and give information on the screen when `Roll is empty`, `The print mark is not in right position`, `The bags are jammed on the welding area`.