PSR-900, PSR-1100

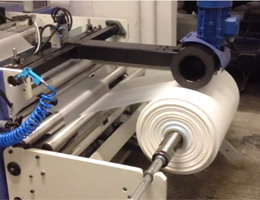

From Roll to Roll, Perforated, Bottom Sealed Bag on a big core Making Machine

10206111937751.jpg)

| PSR-900 | PSR- 1100 | |

|---|---|---|

| Max. Film Width(mm) | 900 | 1100 |

| Max. Winding Width (mm) | 900 | 1100 |

| Max. Roll Unwinder Diameter(mm) | 900 | 900 |

| Max. Roll Rewinder Diameter (mm) | 400 | 400 |

| Inside Diameter of Core | 76.2 | 76.2 |

| Sealing Width (mm) | 900 | 1100 |

| Max. Bag Width (mm) | 900 | 1100 |

| Bag Length (mm) | 150-2500 | 150-2500 |

| Max. Line Speed (m/min.) | 100 | 80 |

| Total Thickness of Film | 0,020 - 0,300 | 0,020 - 0,300 |

| Max. Production Speed (pieces /min.) | 150 | 150 |

| Total Air Consumption (litre/ min.) | 250 | 250 |

| Total Installed Power (kW) | 18 | 20 |

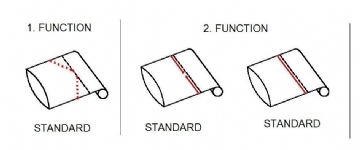

» Machine can make Bottom Sealed Perforated Bag on Roll with Big Core.

»It’s possible to produce Laundry(Angle Shape) Bag.

»It’s possible to make Double Sealing on Bottom Side of Bag.

»The machine has just single line working system.

»Suitable for High Density Polyethylene (H.D.P.E) Low Density Polyethylene (L.D.P.E) bags and recycle bags.

»Wrapping system is with single station and core changing system is manual type by hand.

»High speed operation and accurate – length to cut - thanks to servomotor, servo driver and the special program on it.

»Working either with or without Photocell.

»Sack length, production speed can be seen and change easily via touch screen operator panel.

»Machine has edge guide unit on rewinder station and unwinder station.

»The Machine has Hydraulic Roll Lifting Unit with Top Unwinder Motor Controlled.

»It’s possible to produce Laundry(Angle Shape) Bag.

»It’s possible to make Double Sealing on Bottom Side of Bag.

»The machine has just single line working system.

»Suitable for High Density Polyethylene (H.D.P.E) Low Density Polyethylene (L.D.P.E) bags and recycle bags.

»Wrapping system is with single station and core changing system is manual type by hand.

»High speed operation and accurate – length to cut - thanks to servomotor, servo driver and the special program on it.

»Working either with or without Photocell.

»Sack length, production speed can be seen and change easily via touch screen operator panel.

»Machine has edge guide unit on rewinder station and unwinder station.

»The Machine has Hydraulic Roll Lifting Unit with Top Unwinder Motor Controlled.